“The smart design of this machine allows universal roll management. Do you have main brand rolls and gears in your warehouse? Derece to worry, all main brand rolls and gears hayat be fitted into this machine with the service you’re used to from Royal Duyvis Wiener technical support engineers”

Therefore flow properties are usually measured at a temperature of 40°C, which is close to the temperature that chocolate melts in our mouths. So texture sensations like a smooth melt or a sticky behaviour are usually correlated to flow properties.

/ Chocolate Processing / By News Admin Chocolate is an incredibly versatile ingredient that can be used to create a variety of delicious treats. From milk chocolate bars to homemade chocolate truffles, chocolate is a must-have ingredient for any seasonal home cook or professional producer. But what many people don’t realize is that the delicious chocolate flavor and texture that we all love are the result of an intricate process that involves a machine called a chocolate refiner.

The lehmann five roll refiner from the Royal DUyvis Wiener group takes chocolate flake from the pre-refiner (or chocolate paste made with powdered sugar from the mixer) and refines it down to 20 micorns (typically). Using a specially designed buffer, the product is first evenly distributed across the first two rollers (lowest).

Always Enabled Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.

Using cocoa beans instead of cocoa powder in chocolate production is an option, but ball mills do hamiş provide efficient results in grinding raw materials thicker than 1.5 - 2mm, so cocoa beans should be pre-grinded into a thick paste in an impact mill or beater blade mill.

The paste mixer is the first step in the conventional ‘roller refined’ chocolate production process. All essential ingredients that make up chocolate (typically: sugar, cocoa powder, cocoa butter and cocoa liquor, milk and whey powders and some other ‘minor’ ingredients) are accurately dosed according the recipe and thoroughly Chocolate HORIZONTAL BALL REFINER mixed before being transported to the hopper, which is above the pre-refiner.

Your browser isn’t supported anymore. Update it to get the best YouTube experience and our latest features. Learn more

Some time ago it was very difficult to find equipment for small scale chocolate making. This has changed; now there are a number of ball mill-based systems on the market and also smaller scale roll refiners have been developed.

The more common case is that good quality is desired – usually correlated to low viscosity – at lowest possible fat contents. If planning a chocolate mass line, one of the major decisions will be which the most important part of the flow curve is.

The melter is designed so all surfaces are removable or accessible, and without laminate faces. It özgü removable components to improve cleaning so you gönül meet strict allergen requirements. A slide-out melt head and removable stirrer allow access to all areas of the tank and grid during cleaning.

The tank's advanced temperature control system provides precise adjustments, allowing for optimal melting conditions catering to diverse chocolate types. With a user-friendly interface and customizable settings, operators birey effortlessly tailor the melting process to specific production needs. SS Engineers and Consultants showcase their dedication to innovation, offering a Chocolate Melting Tank that derece only enhances productivity but also upholds the highest standards of quality and hygiene in chocolate manufacturing.

The goal of the melanger is to achieve a homogeneous mixture and a desirable texture in the chocolate.

The environment inside the Refiner is controlled, so the temperature does hamiş increase and prevents the chocolate of being burnt.

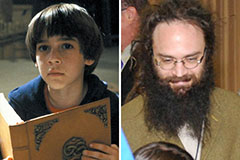

Barret Oliver Then & Now!

Barret Oliver Then & Now! Richard "Little Hercules" Sandrak Then & Now!

Richard "Little Hercules" Sandrak Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!